Chrome Plating and Chromic Acid Anodizing Operations

Contacto

Categorías

What is Chrome Plating and Chromic Acid Anodizing?

Hexavalent chrome plating, or simply chrome plating, is the electrical application of a coating of chrome onto a surface for decoration, corrosion protection, and durability. An electrical charge is applied to a tank containing a chrome solution. The electrical charge causes the chrome metal particles in the tank to fall out of solution and deposit onto objects placed in the plating solution.

Types of Chrome Plating Operations

Hard Chrome Plating

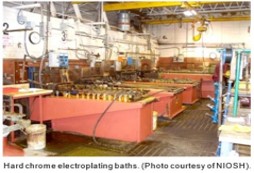

A thick layer of chrome (10 to 500 μm or 0.01 to 0.5 mm, up to the thickness of a dollar bill) is deposited directly on the base metal (usually steel) to provide a smooth surface that is resistance to wear under extreme conditions. Tanks used in hard chrome plating operations contain chromic acid (containing hexavalent chrome), sulfuric acid, and water. Chrome electroplating requires constant control of the plating bath temperature, electrical power, plating time, and bath composition. Example parts include hydraulic cylinders, rotors, bearings, and agricultural equipment.

Decorative Chrome Plating

A thinner layer of chrome (0.003-10 μm or 0.00003 -0.01mm, up to the thickness of fine particulate matter) is deposited usually over a layer of nickel previously placed on the base material (e.g., brass, steel, aluminum, or plastic) for looks and basic wear protection. Decorative electroplating baths operate on the same principle as the hard chrome plating process, but requires shorter plating times and operates at lower electrical power. Example parts include car parts, musical instruments, tools, and furniture.

Chromic Acid Anodizing

Chromic acid anodizing is used primarily on aircraft parts and architectural structures that are subject to high stress and corrosion. Chromic acid anodizing is done via a different electrical process than hard or decorative plating and is used to provide a thin oxide layer (around 0.03 μm or 0.0003 mm, about 1/1000th the size of a human hair) on aluminum that imparts the following properties: corrosion protection, electrical insulation, and ease of coloring. Example parts include aerospace components and precision machined parts.

Health Effects of Exposure to Hexavalent Chrome

Inhalation of hexavalent chrome over time may cause:

- Lung and nasal cancers

- Respiratory irritation

- Nasal and skin ulcerations and lesions

- Perforation of the nasal septum

- Allergic reactions including dermatitis and asthma

Exposed Workers

Workers who breathe in hexavalent chrome may experience irritation of the nose and throat. They may also show symptoms including sneezing, coughing, running noses, itching and burning. Repeated or lengthy exposures may cause sores in the nose, resulting in nosebleeds. Over time, some workers develop allergies to hexavalent chrome. For them, inhaling the particles may cause asthma symptoms.

Exposed Communities

Many chrome plating facilities are located in urban, low-income areas. They can expose nearby residents to hexavalent chrome and other dangerous byproducts that can lead to increased cancer rates in the surrounding populations. Because of the potential damage to the environment that metal finishing can cause, chrome plating facilities must treat their wastewater before releasing it. The byproducts also must go through a rigorous disposal protocol because of the dangers they pose.

For more information visit CARB Chrome Plating ATCM webpage.