Underfired Charbroiling Control Technology

- Technology Clearinghouse

- Community Air Protection

- Community Support Tools

- User Guide

- Clearinghouse Tools

- Tool: Current Air District Rules

- Tool: Air District Rule History

- Tool: CARB Regulations

- Tool: BACT Determinations

- Tool: BACT Guidelines

- Tool: Residential Appliances

- Tool: Residential Backup Power

- Tool: Commercial Emergency Backup Power

- Tool: Underfired Charbroiling

- Tool: Attainment Status Lookup

- Request: Next Gen Evaluation

- Standard Categorization Lists

- Training Videos

- Community Questions

- Stationary Source Permitting

Contact

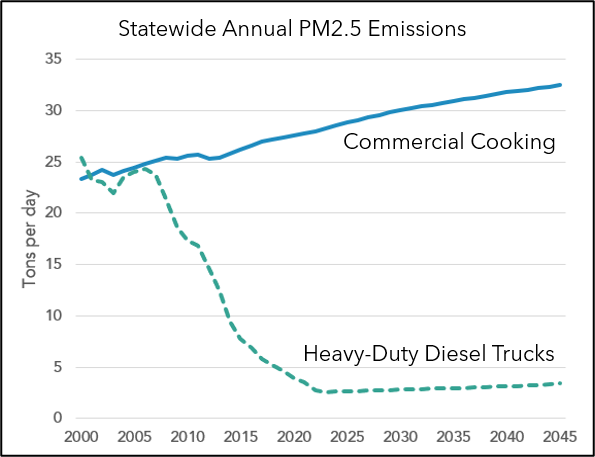

Reducing fine particulate matter (PM2.5) emissions from charbroiling operations in California is critical to meeting federal health-based PM2.5 standards in the South Coast and San Joaquin Valley. In addition, the U.S. Environmental Protection Agency has lowered the PM2.5 standard to 9.0 micrograms per cubic meter making it more protective. There are many other areas in California that may also need to consider reducing emissions from commercial charbroiling and other sources to meet the more stringent standard.

California is home to regions with some of the worst PM2.5 air quality in the nation. Numerous health effects studies have linked exposure to PM2.5 to increased severity of asthma attacks, development of chronic bronchitis, decreased lung function in children, increased hospitalizations, and even premature death in people with existing cardiac or respiratory disease. The California Air Resources Board is responsible, alongside local air pollution control districts, for developing strategies to deliver clean air for all Californians and to bring any areas with excessive pollution into attainment of health-based federal air quality standards. Many direct sources of pollution contribute to the State’s PM2.5 air quality challenges, including heavy-duty trucks, windblown dust, residential wood combustion, and farming operations. Reductions in emissions from these sources are needed to meet air quality standards and improve public health.

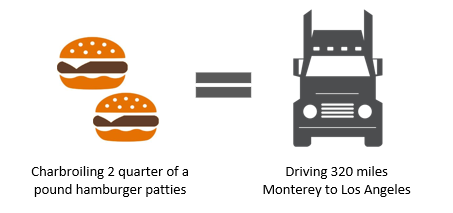

Commercial underfired charbroiling operations are an important and growing source of PM2.5 pollution in many parts of the State. Not only does charbroiling impact regional PM2.5 air quality, it has an outsized local impact on nearby communities.

An underfired charbroiler is a cooking device with a metal grill similar to that of a home barbeque that uses gas, electricity, or solid fuel like wood or charcoal located under the grill to provide heat to cook the food. Since most commercial cooking PM2.5 emissions come from underfired charbroilers, it is important to understand technologies that can control emissions from this key contributor.

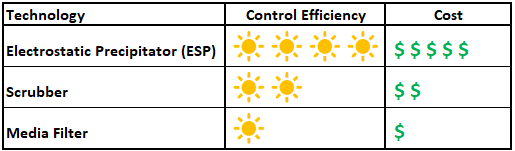

Various types of technologies are available to control PM2.5 emissions from underfired charbroilers. Electrostatic precipitators (ESP), scrubbers, and media filters are commercially available and have been deployed at many locations across the nation.

| Technology Type | Description |

|---|---|

| Electrostatic Precipitators (ESP) | Applies a high-voltage electrostatic charge to the pollution and then uses oppositely charged plates to collect them. The charged plates have to be periodically cleaned. |

| Media Filters | Uses filter materials to trap the pollution. The filter must be replaced periodically. |

| Scrubbers | Fluid is sprayed into the exhaust stream where it fastens to or alters the pollution and can then be filtered out of the exhaust. The fluid spray droplet size may play a role in control efficiency and depend on manufacturer design. Filter media must be cleaned or replaced periodically |

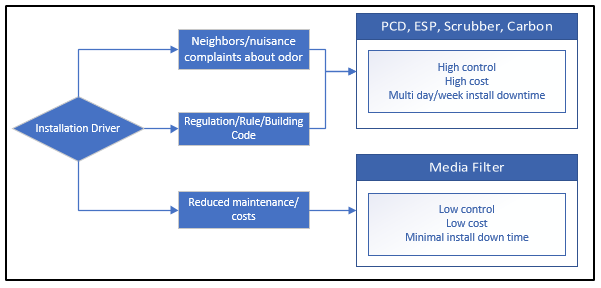

Restaurants commonly install these control technologies in response to odor complaints or due to building code- or site-related restrictions, such as location in a high-rise or at an airport. Restaurants may also be motivated to switch to higher efficiency media filters in order to reduce maintenance costs.

The cost of installing and maintaining control technologies and the emissions reductions that can be achieved depend heavily on the specific commercial cooking operation. Numerous factors impact overall cost and efficiency, including the type and volume of meat cooked, building design, number of floors, location of restaurant, control level, ease of use, etc.

ESPs generally cost more than other technology options and can be challenging to install on existing locations, but they are very effective at removing pollution and are currently the most used technology based on currently available data shown in the tool below. The tool contains installations of underfired charbroiler emissions controls provided by technology manufacturers and vendors across the country. You can explore installations by technology type, location, company, or vendor.

Media filters installed in the existing hood ventilation infrastructure lend themselves well to retrofitting existing locations. Media filters provide the lowest cost option and lowest control efficiency ranging between 10 percent and 50 percent.

The technology to reduce the unhealthy PM2.5 emissions from charbroilers is currently available and can be installed and maintained at a relatively low-cost. The health benefits of lowering these emissions will be primarily felt in the communities where these businesses operate which are often disadvantaged communities.

Please contact us at TechnologyClearinghouse@arb.ca.gov if you have data that you would like to include in this tool.

Tool

Using This Tool

The focus of the tool can be adjusted by technology type, location, company, or vendor.

Technology Type: Select the technology type from the category tabs at the top of the tool or select the technology within the bar graph on the right. This will filter the data to show how many instances of a particular technology have been installed across the nation.

Location: Select a highlighted state within the map in the center of the tool to show installations within that state. The color saturation indicates the number of installations for the technology and geographic location selected.